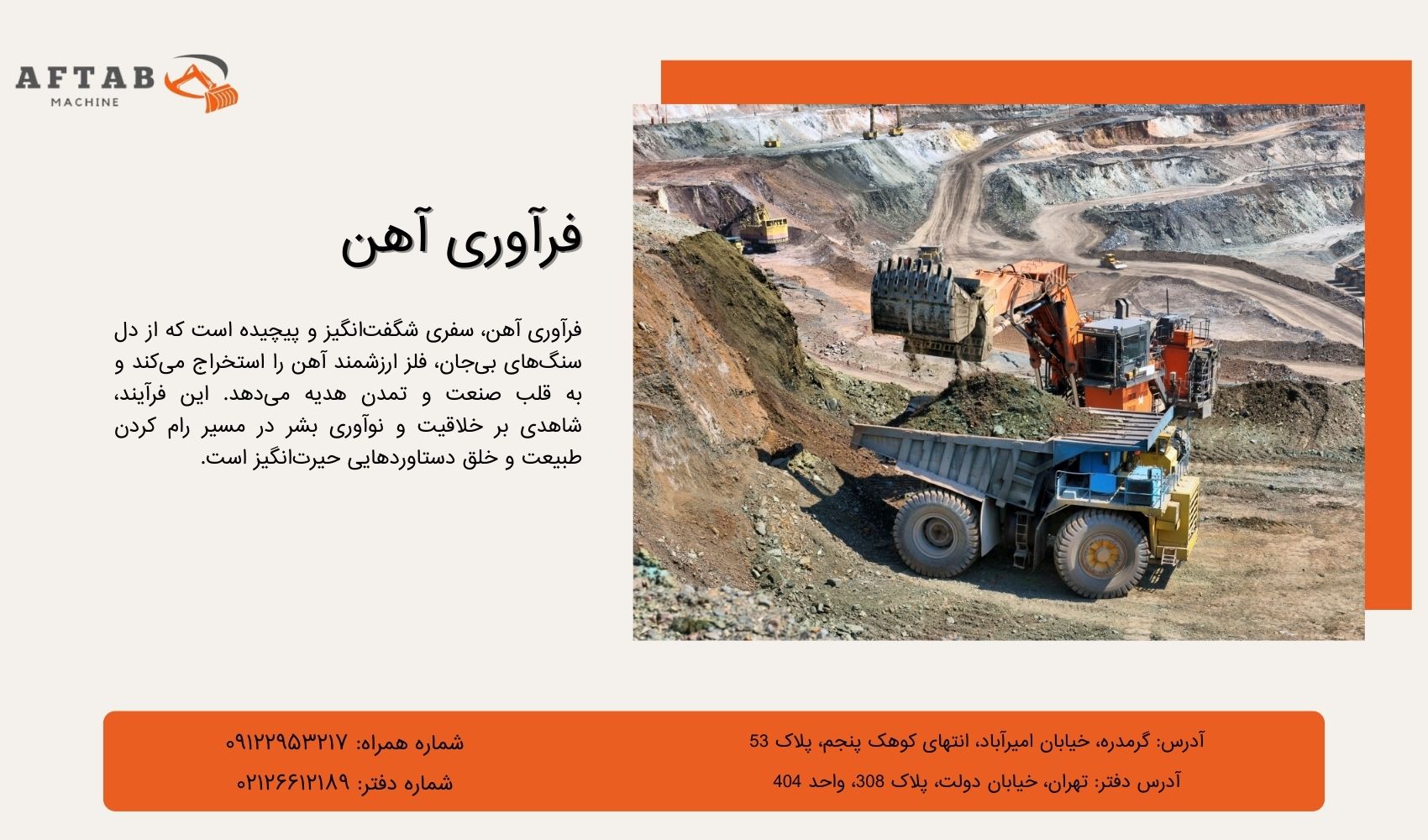

Copper Processing: A Comprehensive Guide From Mining to Refining

Copper processing is an amazing and complex journey that starts from the heart of the ore and ends with its transformation into a pure and useful metal. This process, which forms the beating heart of the copper industry, plays a vital role in the modern world.

In this article, as a copper processing specialist, we will take you on a journey in this faszinierend world and examine step by step the various stages of extraction and purification of this valuable metal.

First, we will have an overview of the copper processing process, and then we will discuss the various methods of extraction and purification of this metal, including leaching, flotation, smelting and electrolysis. In the following, we will discuss in detail the types of copper processing, such as copper sulfide processing, copper cathodic processing, copper oxide processing, and acid copper processing.

Finally, by summarizing the material, we will discuss the importance of this complex process in the extraction of copper and its vital role in various industries, including electricity, construction, and home appliance production. Reading this article will help you gain a deeper understanding of the world of copper, the challenges and subtleties of its processing and the irreplaceable role of this metal in today’s world.

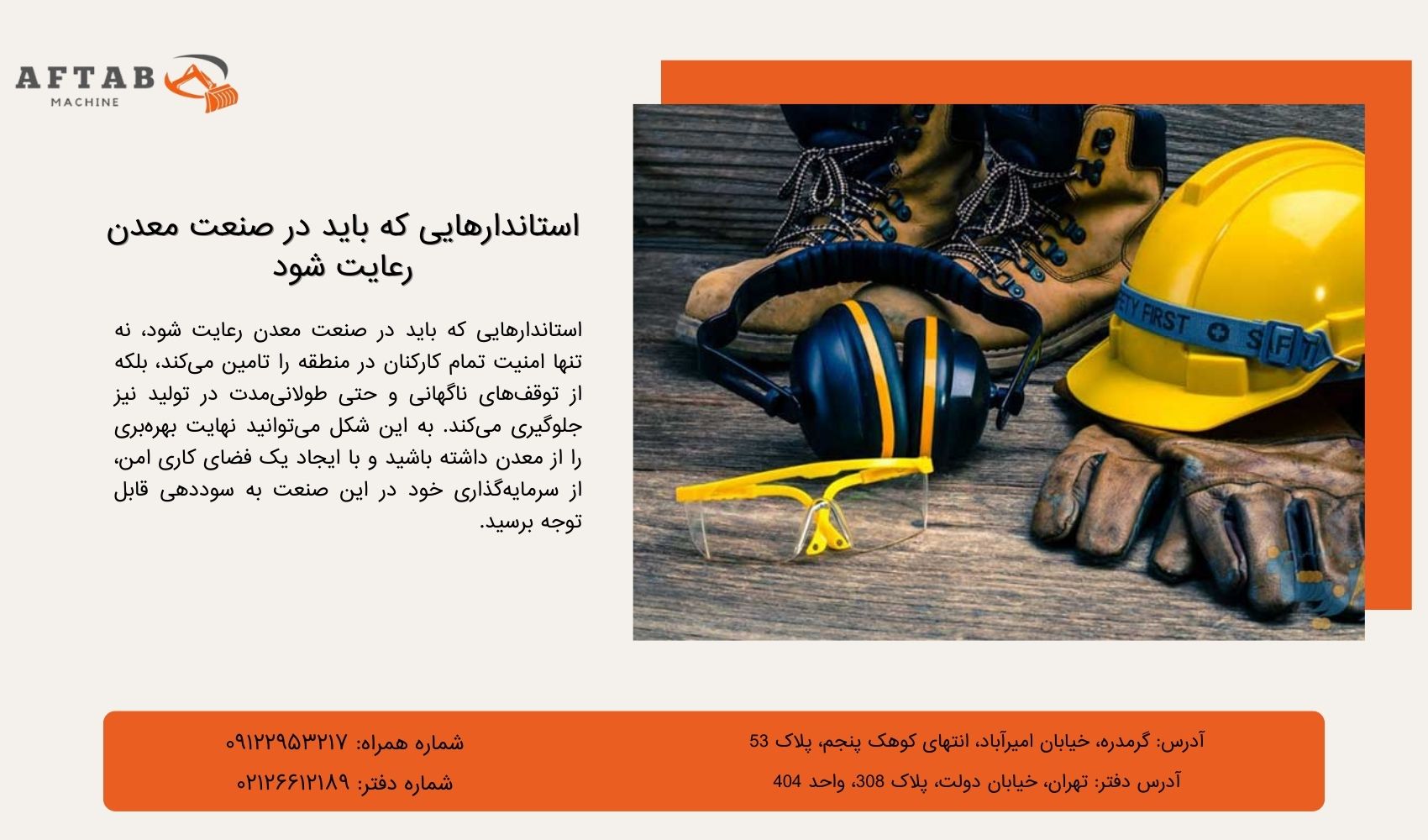

Methods and process of copper processing

Copper, a red-colored metal that has many applications in various industries, is extracted and purified from the heart of the ore after a complex and multi-stage process. In this article, as a copper processing specialist, we will examine the various methods of this process. There are two main methods for processing copper: pyrometallurgy and hydrometallurgy.

Pyrometallurgy

In the pyrometallurgy method, heat and chemical reactions are used to extract copper from ore. The main steps of this method are:

Grinding: Copper ore is ground into small pieces to increase its contact surface with chemicals.

Concentrating: Using various methods such as flotation, copper particles are separated from impurities and copper concentrate with a higher grade is obtained.

Smelting: The copper concentrate is melted in the furnace and the impurities are separated from the metal.

Conversion: In this step, the remaining impurities are separated from copper and raw copper metal is obtained.

Advantage: This method is suitable for high grade ores and is a fast and relatively cheap process.

Disadvantages: This method can cause a lot of pollution and is not suitable for low grade ores.

Hydrometallurgy

In the hydrometallurgy method, chemical solutions are used to dissolve copper from the ore and then separate it using different methods such as electrolysis. The main steps of this method are:

Grinding: Similar to the pyrometallurgical method, the copper ore is ground into small pieces.

Leaching: The milled ore is treated with appropriate chemical solutions such as sulfuric acid or hydrochloric acid to dissolve the copper in it.

Purification: The solution containing copper is purified using different methods such as precipitation, evaporation or ion exchange.

Electrolysis: In this step, pure copper is separated from the solution and deposited as thin sheets (cathode) on the cathode electrode.

Advantage: This method is suitable for low-grade ores and produces less pollution than the pyrometallurgical method.

Disadvantages: This method is a slower and more expensive process than the pyrometallurgical method.

The choice of copper processing method depends on the type of ore, copper grade, economic conditions and environmental considerations. In the following sections, we will examine the details of each of these methods, their advantages and disadvantages, and the applications of each method. Also, we will introduce new copper processing methods such as bioleaching and solvent extraction.

Copper processing by leaching method

Leaching, one of the copper processing methods, is a process in which chemical solutions are used to dissolve the copper from the ore. This method is especially suitable for higher grade copper oxide ores.

In the leaching process, the following steps are performed:

Grinding: Copper ore is ground into small pieces to increase its contact surface with the chemical solution.

Dissolving: The milled ore is mixed with a suitable chemical solution, such as sulfuric acid or hydrochloric acid. At this stage, the copper in the ore dissolves in the solution and the impurities remain.

Purification: The solution containing copper is purified using different methods such as precipitation, evaporation or ion exchange.

Electrolysis: In this step, pure copper is separated from the solution and deposited as thin sheets (cathode) on the cathode electrode.

Advantages of leaching

This method is suitable for high grade ores.

It creates less pollution than traditional melting methods.

It is a relatively flexible process and can be used to extract copper from different types of ores.

Disadvantages of leaching

This method is a slower and more expensive process than traditional melting methods.

Not suitable for low grade ores.

Leaching is an important method in copper processing, which is especially useful for extracting copper from low-grade ores that cannot be processed by traditional methods.

Copper processing by flotation method

Flotation, one of the copper processing methods, is a process used to separate copper mineral particles from impurities using air bubbles. This method is especially suitable for high-grade copper sulfide ores.

In the flotation process, the following steps are performed:

Grinding: Copper ore is ground into small pieces to increase its contact surface with chemicals.

Addition of reagent: special chemical reagents are added to the milled pulp. These reagents bind to the copper mineral particles and render them hydrophobic, while the impurities remain hydrophilic.

Aeration: The milled pulp is aerated to create air bubbles.

Separation: Air bubbles attach to hydrophobic copper mineral particles and carry them to the surface of the pulp, while hydrophilic impurities sink to the bottom of the pulp.

Concentrate collection: The foam containing copper mineral particles is collected and known as copper concentrate. The separated impurities are discarded as waste.

Advantages of flotation

This method is suitable for low grade ores.

It is a relatively quick and cheap process.

It can also be used to recover copper from waste.

Disadvantages of flotation

This method can cause a lot of pollution.

It is not suitable for high grade ores.

Flotation is an important method in copper processing that is widely used to extract copper from high-grade sulfide ores.

Types of copper processing

Copper, a red metal that is used in various industries, is extracted and purified after a complex process using different methods. In this article, as a copper processing specialist, we will examine the types of these methods.

Copper sulfide processing: This method is the most common copper processing method and is used for copper sulfide ores that have a low grade. The main steps of this method include grinding, concentration, melting and conversion.

Cathodic copper processing: In this method, pure copper is produced in the form of thin sheets (cathode) through electrolysis. This method is used to produce high quality copper, especially for electrical purposes.

Copper Oxide Processing: This method is used for higher grade copper oxide ores. In this method, chemical reactions are used to dissolve copper in acid and then separate it using different methods such as electrolysis.

Copper processing with acid: In this method, acid is used to dissolve copper from the ore and then separate it using different methods such as electrolysis. This method is used for low-grade ores or ores that cannot be processed by other methods.

Copper processing with bioleaching: In this new method, microorganisms are used to dissolve copper from ore. This method has many environmental advantages over traditional methods, as it significantly reduces acid consumption and pollutant production.

Copper processing by solvent extraction: In this method, organic solvents are used to dissolve copper from the ore and then separate it. This method is used for low-grade ores or ores that cannot be processed by other methods, especially for complex ores that contain many impurities.

Choosing the type of copper processing depends on various factors, including the type of ore, copper grade, economic conditions and environmental considerations. In the following sections, we will examine the details of each of these methods, their advantages and disadvantages, and the applications of each method.

Cathodic copper processing

Cathodic copper, the purest type of copper, is extracted from raw copper through a chemical-electrical process called electrolysis. This method is used to produce high quality copper and specifically for electrical applications that require high electrical conductivity.

The main stages of cathode copper processing are:

Electrolyte preparation: A solution containing copper salts is prepared in water.

Anode: Raw copper is placed as anode in the electrolysis cell.

Cathode: Thin sheets of pure copper are placed in the electrolysis cell as the cathode.

Application of electric current: Electric current is applied from anode to cathode.

Copper purification: during the passage of electric current, copper ions are separated from the anode and move towards the cathode and are deposited on it as pure copper. Impurities in raw copper remain in solution.

Washing and drying: cathode copper sheets are removed from the cell, washed and dried.

Advantages of cathode copper processing

Production of high quality copper with high electrical conductivity

A relatively clean and environmentally friendly process

The possibility of recovering copper from waste

This method is suitable for high grade ores.

Disadvantages of cathode copper processing

A relatively slow and expensive process

Needs a lot of electrical energy

Application of cathode copper processing

This method is used to produce high quality copper for various applications such as wire and cable, copper pipes, heat exchangers and electronic components.

Copper sulfide processing

Copper sulfide, the beating heart of the copper industry, is extracted from the heart of the sulfide ore and then turns into a useful red metal through a complex process. This method is the most common copper processing method and is suitable for low grade ores.

The main stages of copper sulfide processing are:

Grinding: The copper ore is ground into small pieces to prepare for the next steps.

Concentrating: through various methods such as flotation or flotation, copper mineral particles are separated from impurities and high grade copper concentrate is produced.

Smelting: Copper concentrate is melted in high temperature smelting furnaces and turns into matte. In this step, impurities such as sulfur are separated from copper.

Conversion: matte copper reacts with oxygen in conversion furnaces and turns into raw copper or blister.

Purification: raw copper is purified by passing through electrolysis and the remaining impurities are separated from it. Refined copper is made into ingots or wire and is prepared for various applications.

Advantages of copper sulfide processing

This method is suitable for low grade ores.

It is a relatively fast and efficient process.

It can also be used to recover copper from waste.

Disadvantages of copper sulfide processing

This method can create a lot of pollution, especially if proper pollution control methods are not used.

Not suitable for high grade ores.

Application of copper sulfide processing

This method is used to process a wide variety of low-grade copper sulfide ores and plays an essential role in the production of copper for various industries such as construction, electricity, and home appliances.

summary

Copper, a red-colored metal that has many applications in various industries, is extracted from the heart of the ore and after going through a complex process and using different processing methods, it is pure and ready to be consumed. Each of these methods has its own advantages and disadvantages and is suitable for a particular type of ore or economic conditions. Choosing the right copper processing method depends on factors such as ore type, copper grade, environmental and economic considerations. Finally, each of these methods plays an essential role in the extraction of this valuable and useful metal. In this article, we briefly reviewed some common methods of copper processing, including copper sulfide, cathode, oxide, and acid processing.

The most common copper processing method is copper sulfide processing, which is used for copper sulfide ores, which are the most common type of copper ore.

Copper is used in various industries including electricity, construction, home appliance manufacturing, and aerospace industries.

Copper is a metal with high conductivity, excellent malleability and ductility, and corrosion resistance.