Strict mining rules and regulations: why should they be followed?

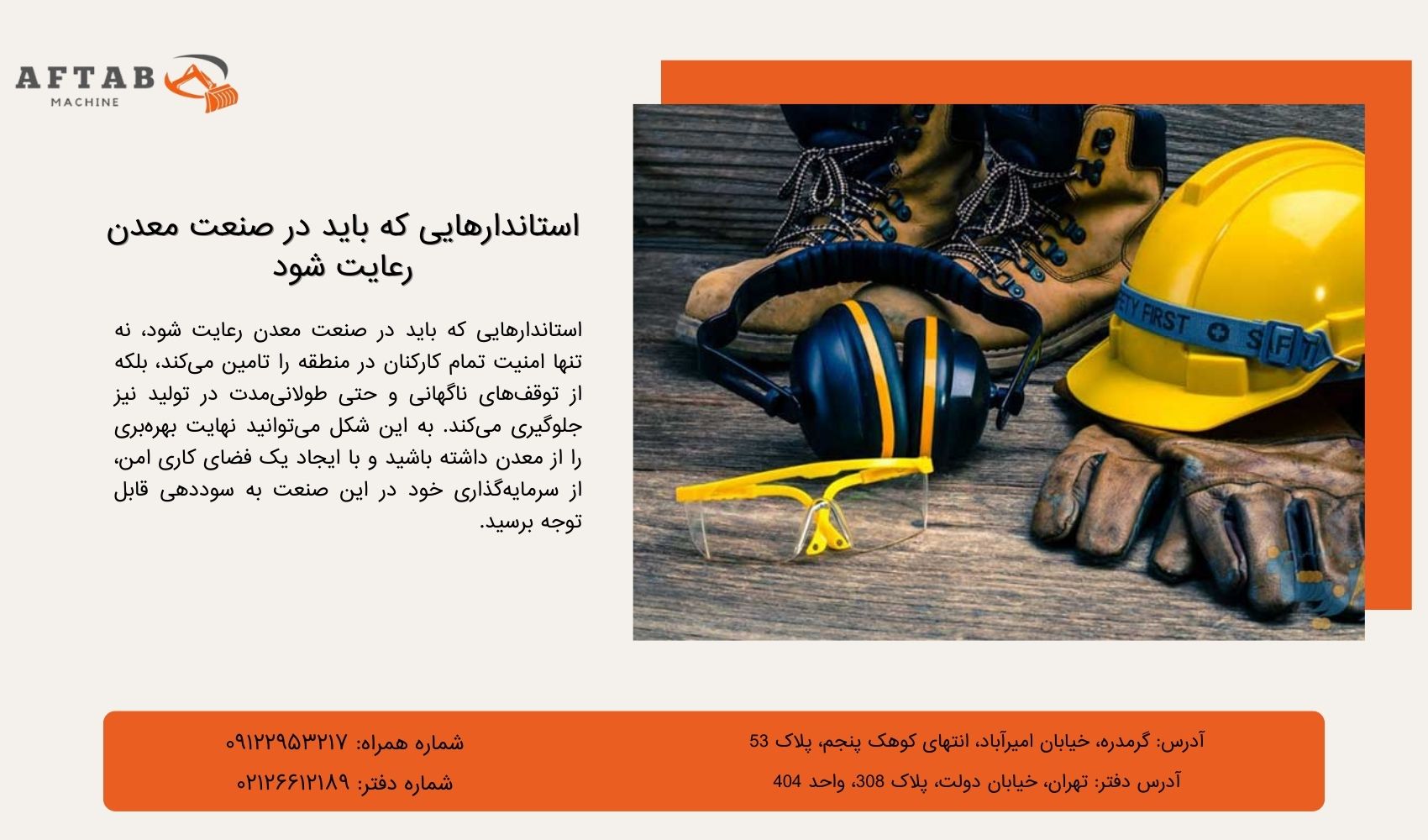

The standards that must be followed in the mining industry not only ensure the safety of all employees in the area, but also prevent sudden and even long-term stoppages in production. In this way, you can get the most out of the mine and by creating a safe working environment, you can achieve a significant profit from your investment in this industry. In this article, we talk about the standards that must be followed in the mining industry.

Mining industry standards

The mining industry is one of the most dangerous industries that requires strict compliance with safety standards to maintain the health and safety of employees. These standards have been compiled from various sources, including international organizations and institutions, and serve as comprehensive guidelines for improving occupational health and safety conditions in mines.

ISO standards

The International Organization for Standardization (ISO) has developed a set of specialized standards for occupational health and safety management in various industries, including mining. The ISO 45001 standard is recognized as a global standard in this field and provides a systematic approach to identify, assess and control risks in work environments. By implementing this standard, companies can reduce the risks associated with mining activities and provide a safer work environment for their employees.

ICMM standards

The International Council of Mines and Metals (ICMM), as a global body in the mining industry, has compiled a set of safety principles and standards. These standards focus on risk management, continuous training of employees and continuous improvement of safety systems. With the aim of improving the level of safety in the mining industry, ICMM introduces the best methods and safety standards to its members and monitors their effective implementation.

OHSAS 18001 standards

The OHSAS 18001 standard is also known as another international standard in the field of occupational health and safety management. This standard helps organizations to implement an effective occupational health and safety management system and continuously improve it. By using this standard, companies can improve safety conditions in the workplace and prevent accidents and occupational diseases. The number of standards published by the International Organization for Standardization (ISO) is constantly increasing, which indicates the increasing importance of standardization in the field of occupational health and safety.

Safety standards in Iran's mines

In Iran, the Ministry of Cooperation, Labor and Social Welfare and the National Standards Organization have compiled a set of safety rules and regulations with the aim of improving the safety and health of employees in the mining industry. These regulations help create safer workplaces by covering a wide range of topics, including safety training, use of personal protective equipment and environmental management.

Safety regulations in mines

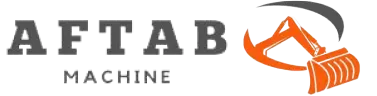

Safety regulations in mines refer to a set of rules and guidelines that have been compiled with the aim of preventing accidents and maintaining the health and safety of employees. These regulations include the following:

All mine workers are required to periodically receive safety training. These trainings include getting to know the dangers in the workplace, how to use safety equipment correctly, and accident prevention methods. Continuous trainings help employees to become familiar with the latest safety methods and techniques and benefit from them in practice.

The use of personal protective equipment such as helmets, gloves, glasses and safety shoes is mandatory for all employees. As a protective layer, these equipments protect employees from possible injuries.

Mining companies are obliged to continuously identify, evaluate and take necessary measures to reduce risks in the work environment. This process includes identifying risks, assessing their probability and severity, and developing risk control plans.

All equipment and machinery used in mines must be regularly inspected and maintained to ensure their correct and safe operation. Regular maintenance and careful inspection of equipment minimizes the possibility of accidents caused by equipment failure.

Compliance with environmental standards is also an integral part of safety regulations in mines. These regulations include industrial waste management, control of air, water and soil pollution and protection of natural resources. Proper environmental management helps to reduce the negative effects of mining activities on the environment and the health of employees.

Challenges and solutions to improve safety in mines

The implementation of safety standards in the mining industry is associated with several obstacles that make it a challenge to establish optimal safety. In the following, we will examine some of these challenges and effective solutions to overcome them.

High costs of equipment and training

Investing in advanced safety equipment and conducting specialized training courses imposes significant costs on mining companies.

Allocating sufficient funds, benefiting from government support programs, renting equipment and joint purchases with other companies can help reduce the financial burden of these costs.

Resistance to change

Some employees and managers may resist changes in safety procedures and equipment.

Creating a safety culture in the organization, increasing employees’ awareness of the importance of safety, holding briefing sessions and showing the positive results of using new equipment can help reduce this resistance.

Complexity of safety regulations

The multiplicity and complexity of safety laws and regulations make their strict implementation difficult.

Using safety consultants and experts to interpret and correctly implement the rules, using safety management software to simplify processes can help solve this challenge.

Recommendations for improving safety in mines

Improving safety in mines requires a comprehensive and continuous approach that includes the cooperation of all stakeholders, including employees, managers, government and safety consultants. By adopting appropriate solutions and creating a strong safety culture, it is possible to significantly improve the level of safety in mines and prevent accidents and injuries.

Creating an organizational culture where safety is a priority and all employees adhere to it plays a key role in improving safety conditions.

Encouraging employees to actively participate in safety programs and providing suggestions helps to identify problems and provide effective solutions.

Investing in new technologies, such as monitoring and warning systems, advanced personal protective equipment and robots, will contribute significantly to improving the level of safety.

Continuous training of employees to properly use new equipment and improve their skills helps to reduce accidents and increase safety.

Developing comprehensive and transparent safety policies that cover all aspects of safety will help create a coherent framework for safety improvement.

Continuous inspection and monitoring of the implementation of safety policies and continuous assessment of risks helps to identify problems and continuously improve safety conditions.

summary

The mining industry, despite its economic importance, has always faced safety challenges. Compliance with safety standards not only helps save workers’ lives and reduce financial losses, but also improves productivity, reduces environmental impacts, and promotes corporate social responsibility. The successful implementation of these standards requires the comprehensive cooperation of all stakeholders and investment in education, technology and safety culture. Looking to the future, we must look for new and updated solutions to improve the level of safety in mines so that we can create a safer and more stable future for this industry and society.

Safety, health and environmental standards, such as ISO 45001, are very important in the mining industry.

Compliance with these standards is necessary to save employees’ lives, reduce costs, increase productivity and protect the environment.

Pressure to increase production, high cost, lack of awareness, lack of adequate supervision and resistance to change are among the reasons for not complying with these standards.